KAFO

Banner

COMPANY

MARCH TO THETOP OF TECHNOLOGY

Since the establishment in 1968, KAFO (KAO FONG MACHINERY CO., LTD) keeps growth step by step along with the development of machinery industry in Taiwan based on its solid foundation of superior technology. It is not accidental that it becomes the leading brand of mold processing industry as well as faithful business partner. The key to KAFO’s success is intensifying the know-hows, continuously improving manufacturing process, focusing on the upgrading core competency of technology and sticking to perfection. Besides, the Company has obtained the national certified endorsement, which is rated as the benchmark of the industry.

So far KAFO has accumulated its steady technological capabilities and experiences for over 50 years and successfully developed stable sales performances in the 8 series products of Vertical Machining Center, Double-Column Machining Center, Horizontal Machining Center, High Speed Double-Column Machining Center, Gantry Double-Column Machining Center and Drilling & Tapping Center, facilitating us in expanding global layout centered in Taiwan.

x HISTORICAL EVOLUTION

-

1968

Founded up Kao Fong Iron Works to produce tapping machinery and drilling machine.

-

1972

Restructured as KAO FONG MACHINERY CO., LTD, with the factory set up in Fongyuan city for producing medium and small milling machine. Awarded as an excellent company and export sales guidance factory by Ministry of Economic Affairs.

-

1976

Constructed modern factory at the old site of Daya Village, Taichung County.

-

1981

Developed the first CNC Milling Machine with Extending Arm and Double Knee support (V2-CNC) in Taiwan.

-

1982

Developed the first CNC Duplicating Milling machine (V350-TF) and CNC Special Milling Machine (V350-NF (3H)) were created in Taiwan.

Developed VBM-A Horizontal Boring & Milling Machine. -

1983

Developed composite Type Vertical & Horizontal Milling Machine(G450) and Universal Milling Machine(U450) created by R&D. Obtained considerable orders from home and abroad.

-

1984

Constructed modern factory at the old site of Daya Village, Taichung.

-

1985

Completed 2000 m2 Factory Expansion project.

Developed Bed Type Vertical Composite CNC Boring & Milling Machine(VHNC2060). -

1986

Developed VTC-2270 Vertical CNC Duplicating Milling Machine.

-

1989

Expanded Factory by 4,340m2 and developed various vertical machining centers successfully.

Introduced computerization management system. -

1990

Built up the product line of vertical machining centers series, laid a good foundation of vertical series product.

-

1991

Initial public offering approved Securities and Futures Commission.

Developed VTC-3810 Duplicating Milling Machine and Vertical Machining Center & Duplicating Milling Machine (VMTC series). -

1992

Restructured and introduced a new team to participate in the operations to intensify the development foundation in the future.

-

1994

Developed 9000rpm high speed vertical machining center.

Developed linear guideway vertical machining center (VMC-1060) under the cooperation with Mechanical & Mechatronics Systems Research Laboratories (MMSL), ITRI. -

1995

Passed ISO-9002 certification.

-

1998

OTC approved by Securities and Futures Commission. Capital increased to NT$500 million.

-

1999

Won The 8th Taiwan Excellence Award with VMC-1500 vertical machining center.

Developed BMC-4023 Double Machining Center. -

2000

Signed with a Japanese company-「KASHIYAMA Industry」for technology transfer contract about vacuum pump of semiconductor process equipment.

Passed the certification of ISO 14001 Environmental Management System.

Developed HMC-630 Horizontal Machining Center.

Won THE RISING STAR AWARD granted by the Ministry of Economic Affairs. -

2001

Passed the certification of German TUV-ISO-9001.

Won the 9th Taiwan Excellence Award with VMC-850A Vertical Machining Center. -

2002

Strategy alliance employed to product technology transfer with wet processing equipment technology in clean room of factory.

Won Taiwan Excellence Award with PV 1260 High Speed Double Machining Center.

Created BMC-3022Linear Motor Drive Gantry System based on R&D. -

2003

Completed Plant No. 4, Taichung Factory with sales revenue over NT$1 billion based on capacity expansion.

Invested Kunsan Factory, China to construct plant and put into production formally.

Applied and approved to enter and station in Central Taiwan Science Park. -

2004

Approved and obtained loans of NT$65 million for promoting industrial research and development granted by the Industrial Investment Bureau, Ministry of Economic Affairs.

Started to construct the plant in Central Taiwan Science Park, covering the site area of 427080 square meters and the building size of 505,378 square meters.

Won Taiwan Excellence Award with VMC-11600 Vertical Machining Center. -

2005

Acquired CE certification of professional institution about Vertical and Horizontal Machining Center.

Won Taiwan Excellence Award with HMC-500 Horizontal Machining Center. -

2006

Won Taiwan Excellence Award HMC-630 Horizontal Machining Center.

-

2007

Merged by HOTA INDUSTRIAL MFG.CO.LTD formally, introducing the Japanese technical team.

Completed No.1 Factory, Central Taiwan Science Park, which is put into use and stationed formally.

Entire double series is remodeled. -

2008

Completed No. 2 Factory, Central Taiwan Science Park, which is put into use.

-

2009

Won Excellence Award, Silver Medal and Best Popularity Award with CV-6Vertical Machining Center.

-

2010

Developed double five face machining center RV series.

-

2011

Won Excellence Award with PV-16 High Speed Double Machining Center.

Won Excellence Award with BMC-2616 Double Machining Center. -

2012

Developed CV-9APC/DV-9/DV-11 Vertical Machining Center.

Developed PV-3127(2616) High Speed Double Machining Cente.

Developed Gun Drilling Machine KGD-1000. -

2013

Set up “Taipei Office” in the northern Taiwan.

Set up TAKAWA SEIKI, Inc. a subsidiary in America.

Developed KRV series Column Double Machining Center.

Developed 90°Head.

Developed Vertical Machining Center CV-14/16.

Developed Gun Drilling Machine KGD-1200S/KGD-500-2. -

2014

Won Taiwan Excellence Award with High Speed Double Machining Center PV series(PV-16/PV-1313/PV-1318/PV-1323).

Developed HMC-800 and HMC630-6P Horizontal Machining Center.

Developed Vertical Machining Center FCV-54.

Developed Universal Head. -

2015

Set up “Tainan Office” in southern Taiwan.

Developed Vertical Machining Center CV-7/VMC-2100/3100.

Developed Drilling & Tapping Center KT Series.

Developed 5 Axis Simultaneous Machining Center KFO-620-5AX.

Won Taiwan Excellence Award with Column Double Machining Center KRV Series(KRV-XX32/KRV-XX37/KRV-XX42).

Developed double 5 Axes Machining Center RV5A Series(RV5A-XX35).

Developed gantry 5 Axes Machining Center KG5A Series(KG5A-XX25/KG5A-XX30).

Developed double auto changeable extension head. -

2016

Invested in Huaian Factory, China and formally put into productionCompleted Phase 3 Plant, Central Taiwan Science Park to gain NT$1 billion with expansion of capacityDeveloped Vertical Machining Center SV-1000/CV7-KM/CV-168/DV-168/CV-12.Developed Double Machining Center BMC-2012.Developed Multi Lead &Interface head auto changeable system

-

2017

Developed 5 Axis Simultaneous Machining Center KMU SeriesDeveloped High Speed Double Machining Center PV-1310.Developed Extension Head / Speed-up type Extension Head.Developed Vertical Machining Center DV-12/VMC-126/VMC-1370.Developed High Speed Double Machining Center PV-1310/PV-58.

-

2018

Won Taiwan Excellence Award with High Speed Double Machining Center PV series(PV-58).

-

2019

Won Taiwan Excellence Award with Gantry Type 5-axis Machining Center KG/KG5A series(KG5A-2232).

-

2020

Won Taiwan Excellence Award with 5-axis Machining Center KFO series(KFO-620-5AX).

x Quality and Certification

小巨人獎

ISO 9001

(2017-2020) CERTIFICATE

ISO14001

CERTIFICATE (20150521-20180520)

CV-6 精品獎獎狀

2009

HMC-500 精品獎獎狀

2015

HMC-630 精品獎獎狀

2006

KRV系列 精品獎獎狀

2015

PV-16 精品獎獎狀

2010

PV-1260 精品獎獎狀

2002

PV系列 精品獎獎狀

2014

VMC-168 精品獎獎狀

2008

VMC-850A 精品獎獎狀

2001

VMC-1100 精品獎獎狀

2003

VMC-1500 精品獎獎狀

1999

VMC-11600 精品獎獎狀

2004

工具機之可旋轉電氣箱

140721~231229

工具機之長導螺桿防振機構

140721~231229

工具機用機台結合校正機構

140521~231229

NE1105110006

NE1105110006

NL1105100107

NL1105110016

NL1105110017

NM1105100085

NM1105110008

NM1105110009

ISO 14001 2024-2027

ISO 9001 2015(~2026.02.17)-1

ISO 9001 2015(~2026.02.17)-2

ISO 9001 2015(~2026.02.17)-3

ISO 9001 2015(~2026.02.17)-4

x Process Planning

-

TURN-KEY PROJECT PLANNING

- Meet customer’s processing demand.

- Achieve customer’s required quantity production.

- Carry out automation processing.

- Flexibly used in various products.

-

PROFESSIONAL ENGINEERING TEAM

- Having the most state-of the –art software and hardware provides customers with the proposal to increase the production efficiency.

- Improving the processing efficiency through the work analysis, construction method and application test.

- By Immediate service network to reach efficient service capability.

- Through worldwide service to give supports to all customers.

-

01

CUSTOMIZED

PRODUCTION LINE -

02

UNDERSTANDING

NEEDS -

03

Analysis

and Planning -

04

Proposal

-

05

Order

and Specs Confirm -

06

Production

Process -

07

Installation

and Inspection

If you would like to know more about our services,PLEASE FEEL FREE TO CONTACT US.

RIGHT NOWx Quality Policy Statement

1. The quality and environment policies are stipulated by the President as the operating principle for the quality system of the Company. Besides, the Company allows all members and stakeholders to understand, implement and maintain various environmental management actions through national (international) standards, so as to reach a consensus about risks, collaboratively create sustainable operating environment with perfect systems and high quality for fulfilling our social responsibility.

2. Quality Policy of the Company :

2.1 Quality Policy :

“Promoting comprehensive quality management to satisfy the customer demands”

2.2 Introduction of Quality Policy :

Quality management based on comprehensive quality risk ideas pursues the optimization for people, things and objects. We not only integrate the management work to promote work performance, but also establish rational work flow for outputs of high quality products and services.

- Quality about 「People」 : It refers to the staff competency, know- how, mind in service, team work spirit and work.

- Quality about「Things」 : It involves completion and appropriateness of systems and rule, standardization, rationalization and administration of procedure, contact and communication for smooth operation, simplification of job as well as service quality etc.

- Quality about「Objects」 : It covers quality of products, semi-finished products, raw material, parts and components, maintenance of machine and equipment, and calibration and maintenance of instruments and gauges.

3. Outline of Quality Objectives :

3.1 Quality Objectives :

We perform quality control in accordance with “Standard Operating Procedure for Yearly Target Project:(QW003-01-03)and make announcement separately upon confirmation of quality objectives.

3.2 Overview of Quality Objectives :

The Company regulates the work content for each authorized units based on different annual goals, which is followed by the implementation and review of quality objectives. Quality objectives are determined by the President or discussed during the administrative review meeting in the latter half of the year.

4. Commitment to Quality :

In order to unite all members as one, establish overall business policy and maintain perfect systems collaboratively through International Organization for Standardization(ISO), as well as carry out quality environment management, the President of the Company particularly makes the internal and external CSR commitments with the expectation to take effort to realize it by all our members.

- Adequate resources provided by us.

- Intensive support for the participation of all members.

- Compliance with customer’s regulations and rules.

- Constantly strive for perfection with the goal of sustainability.

- Fulfill CSR with heart.

5. Quality Policy Announcement and Advocacy. The Quality Policy is officially announced with the signature of the President, which shows the determination of the Company and the President, and provides foundation for all members to follow. Besides, the Company will advocate it on the occasion of meeting or educational training and convey it by means of poster, card, official website of the Company for the purpose of making every member and stakeholder to understand, carry out and maintain our quality principle.

Environmental Policy

The Company founded in 1968, is mainly engaged in production and sales for machine center, computer numerical control tool room, and CNC duplicating milling machine with main parts and components of cast iron, electronic computer control and ball screw. For the sake of maintaining life environment and enterprise sustainability, it must improve the manufacturing process and conduct environmental management against contamination in light of risk thinking for comprehension (including interested parties). The President makes commitment to comply with the governmental environment protection measures, relevant laws and regulations as a foundational standard, so as to achieve our stipulated goal and objective and exercise due diligence of environmental protection. We establish and maintain environmental management and document system in terms of successive effective operation with the principle of continuous improvement and contamination prevention based on the issues proposed by internal, external and interested parties. The President formulates several points as follows for our future directions:

- Carry out the concept of pollution prevention and continuous improvement to achieve the balance between environmental protection and economic growth.

- Conform to the environmental protection regulations and other relevant requirements.

- Constantly promote waste management and recycle resource effectively.

- Improve the quality of field operating area and work environment.

- Save energy consumption and promote efficient utilization of energy.

x Management Team Experience

-

Chairman SHEN, KUO-JUNGTaiwan

- MBA, University of Sydney, honorary

- Doctorate, Inter American University

-

Vice President CHEN, CHEN-CHUNGTaiwan

- 南亞工專機械系

- 東記造紙

- 味全

-

Vice President LIAO, JUNG-TUNGTaiwan

- 海洋大學造船工程學

- 台灣造船公司

- 金雨企業

-

Vice President 姜廷基Taiwan

- 陸軍軍官學校

- 欣林天然氣公司

-

Assistant Vice President YU, YU-YITaiwan

- 聯合工專機械科

- 昇岱實業

- 台中精機

-

Assistant Vice President CHEN, CHANG-YUANTaiwan

- 逢甲大學會計系

- 資誠會計師事務所

-

Assistant Vice President WU, SHENG-TUNTaiwan

- 中興大學工學碩士

- 永進機械

-

Manager YEH, YUN-FATaiwan

- 永春國中

- 裕常機械廠

-

Manager, Property Division 阮証義台灣

- 勤益技術學院機械工程科

-

Assistant Vice President CHOU, KUO-CHANGTaiwan

- 萬能工商專工管科

- 恆興機械

- 百毅企業

-

Manager, Manufacturing Division CHANG, CHIN-CHITaiwan

- 新民高中資訊科

OPERATING HEADQUARTERS

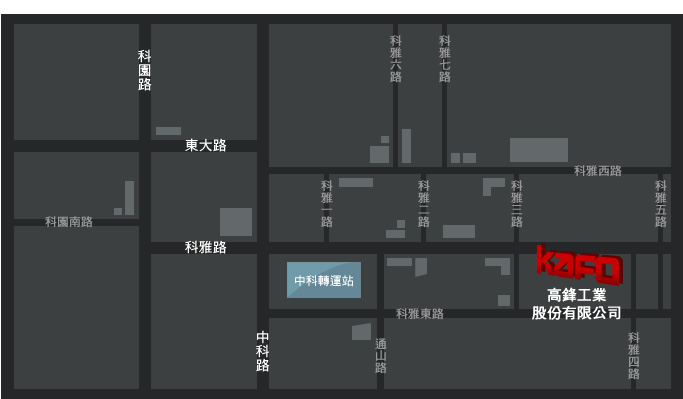

LEARN MOREx Traffic and the surrounding environment

Driving(Highway)

Southern Bound:

- Route of National Freeway No.1: Get off the exit of Daya Interchange (Daya Bound)→go to Chung-Chin Road→ Turn left to Keya Road for the destination of KAFO.

- Route of National Freeway No.3: Get off the exit of Sua-Lak-Khu Interchange(Daya Taichung Bound)→to Chung-Chin Road→ Turn right to Keya Road for the destination of KAFO.

Northern Bound:

- Route of National Freeway No.1: Get off the exit of Taichung Interchange(Sua-Lak-Khu Bound)→to Taichung Port Rd→ Turn right to Dongda Road→ Turn right to Zhongke Rd→ Turn left to Keya Road for the destination of KAFO.

- Route of National Freeway No.3: Get off the exit of Longjing Interchange (Taichung Bound) →connect Zhongqi Road →To Taichung Port Rd→ Turn left to Dongda→ Turn right to Zhongke Rd→ Turn left to Keya Road for the destination of KAFO.

Mass Transportation(Intercity Bus)

Get on the intercity bus of national highway which directly arrives to Taichung (via Taichung Gateway)-such as Kuo-Kuang Intercity Bus, UBus, ALOHA Intercity Bus, HO-HSIN Intercity Bus and get off at the Chun-Chin(ie. Daya)

Interchange and transfer to take a taxi to KAFO.

Mass Transportation(Railway)

Western Line:Get off at Taichung Railway Station and transfer to Taichung Bus No.6 or No. 9 / UBus No. 61 and get off at Daya station and then take a taxi to KAFO.

Mass Transportation(High Speed Rail)