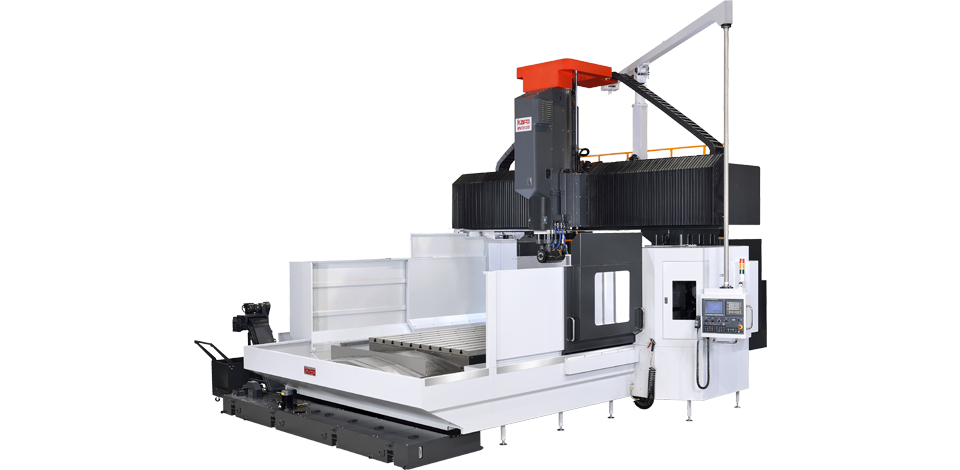

RV Series

Double Column Machining Center

Fixed double column machining center, with automatic exchange system for five-face processing machine series. Able to be equipped with various types of automatic additional head (90 degrees milling head, 45 degreesuniversal head,extension head, speed-up extension head etc.). Equipped with standard vertical/horizontal magazine tool and optional multihead automatic switch system. Angle head has 5° indexing division with high precisionas standard, and 1/2.5° indexing division or CTS function are available. Applicable to the demand of all kinds of parts large castings, structural parts, semiconductor cavity equipment processing, mold processing, aluminum parts, aerospace transportation parts processing needs and so on.

- Automatic head change.

- Automatic tool change.

- 90 degree milling head, A/C universal head, extension head, and speed-up extension head are available for the customer’s requirement.

- There are built-in UNCL-tool hydraulic cylinder in attaching head, able to be changed tool in any position.

- The head storage with exquisite designdoes not occupy any processing space.

- The head storage and magazine tool are tightly protected ty anti-chip scraping sheetmetal.

RELATED PRODUCTS TECHNOLOGY

SPECIFICATION

If you are interested in our products, you can contact us at any time.

CONTACT US PREV SERIES

PREV SERIES

BMC Series

This series is the fix-column bridge type machining center which adopts fixed crossbeam and column, but moveable table . Applicable to all kinds of parts processing, mold mold processing, aluminum parts, aerospace and transportation parts processing industry etc.

NEXT SERIES

NEXT SERIES

RV5A Series

RV5A fixed column five-axis machining center series, combine with world-class high-quality five-axis manufacturing technology, can simultaneously machine a workpiece with one time clamping,by X, Y, Z, A, C five-axis synchronous control, vertical, horizontal and a variety of free angle.