RV5A Series

Double Column Machining Center

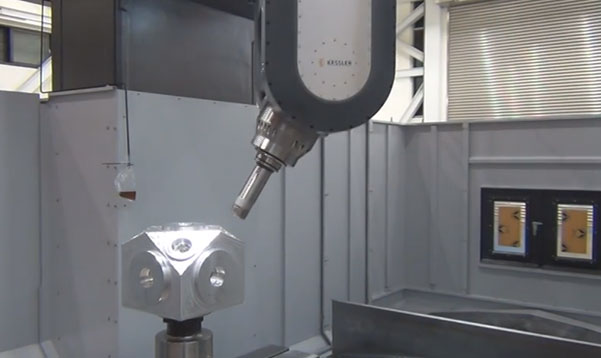

RV5A fixed column five-axis machining center series, combining with world-class high-quality five-axis manufacturing technology, can simultaneously machine a workpiece with one time clamping,by X, Y, Z, A, C five-axis synchronous control, vertical, horizontal and a variety of free angle, which greatly enhances the processing efficiency and production efficiency of large parts,as well as fully meets the processing needs of various industries. Based on different machining applications, to select a high-speed spindle with HSK-A63 24,000 rpm or a strong cutting spindle with HSK-A100 10,000 rpm high torque output. Able to select various fixed column type with different span and travel for different size and weight of workpieces. Applicable to all kinds of parts, semiconductor cavity equipment processing, mold processing, aluminum parts, aerospace transportation parts processing needs and so on. All round cutting solutions provide you the best choice for high value-added products.

- With Heidenhain Linear Scale and closed loop control, improving the accuracy.

- Z-axis with dual-ballscrew design, main spindle and ballscrews are designed on the same axis, with the minimum throat depth design, enhancing the cutting rigidity.

- X-axis is made with dual servo motors design, by using of Master / slave electromechanical control technology, able to provide a stable torque output and improve the dynamic rigidity and poitioningaccuracy of machinery, making a great contribution on acceleration and deceleration processing and precision machining.

- The controller can be used Siemens 840DSL or Heidenhain 640, which can effectively give full play to five-axis synchronous performance.

RELATED PRODUCTS TECHNOLOGY

SPECIFICATION

If you are interested in our products, you can contact us at any time.

CONTACT US PREV SERIES

PREV SERIES

RV Series

Fixed double column machining center, with automatic exchange system for five-face processing machine series. Equipped with standard vertical/horizontal magazine tool and optional multihead automatic switch system. Applicable to the demand of all kinds of parts large castings, structural parts, semiconductor cavity equipment processing, mold processing, aluminum parts, aerospace transportation parts processing needs and so on.

NEXT SERIES

NEXT SERIES

BMC Series

This series is the fix-column bridge type machining center which adopts fixed crossbeam and column, but moveable table . Applicable to all kinds of parts processing, mold mold processing, aluminum parts, aerospace and transportation parts processing industry etc.